|

THE QUALITY OF SYRUPS USED FOR BEE FEEDING

THE QUALITY OF SYRUPS USED FOR BEE FEEDING BEFORE WINTER AND THEIR SUITABILITY FOR BEE WINTERING V i o l e t a C e k s t e r y t e , J u r g i s R a c y s Lithuanian Institute of Agriculture, Instituto Aleja 1, Akademija, 58344 Kedainiai distr. Received 31 March 2005; accepted 07 March 2006 S u m m a r y The quality of several inverted syrups was assessed: Bioinwert, Apiinvert, HI, GF56, GF85, GF56+GF85 and Pchelit. Variations in the quality of the syrups Bioinwert, Apiinvert and HI were determined in the experiments carried out in summer in the isolators after bees had deposited the food in the nucleus combs. Our tests showed that bees purified syrups. The sugar syrups Bioinwert A, Apiinvert A from 1999 and HI from 2001 had content of hydroxymethylfurfural (HMF) 85.9, 32.7 and 1.43 mg/kg, respectively. HMF declined when bees processed those syrups and deposited in the combs. The content of HMF in syrups Bioinwert B, Apiinvert B, HI amounted to 16.1, 2.64 and 0, respectively. The content of HMF in sugar syrups GF 85, GF 56, GF 85+GF 56 used for feeding wintering bees was 5.8, 48.0, 27.7 mg/kg. No HMF was identified in Pchelit. The food deposited in the nucleus combs by bees had more biological active components compared with the food fed to bees. Diastase activity does not exist in Bioinwert A from 1999 and 2000 nor does it in Apiinvert A from 1999. This component appears in Bioinwert B – 3.88 and 6.07 Gothe units and Apiinvert B – 6.69 Gothe units. Saccharose present in the syrups S (A) from 2000 and 2001 was 47.0% and 47.8%. Due to the effect of invertase present in the bee secretion, the syrups S (B) contained only 11.6 and 6.75 % of saccharose. Low invertase activity 2.18 and 16.9 IU was determined in Bioinwert A from 1999 and 2000, however the activity of this enzyme increased after processing of the syrups by bees – in the Bioinwert B from 1999 it amounted to 64.6 and 53.6 IU and in Apiinvert B to 41.9 UI. The sugar syrups GF 56, GF 85, GF 56+GF 85 and Pchelit were used for feeding wintering bees. The highest food consumption 1.9 kg/comb was identified for bees fed on GF 56, however those colonies reared fewer brood. In spring crystallisation of GF 56 syrup was observed in few cells of the comb. The strength of the bee colonies after wintering on this syrup slightly declined from 5 points estimated in the autumn to 4.5 estimated in the spring. The best wintering of bee colonies was observed on syrups Pchelit and GF 56+GF 85. The number of brood after wintering in those bee colonies in spring was 220 and 162 in hundred cells; the food consumption in those colonies was 1.4 and 1.5 kg/comb, respectively. All bee colonies survivied through winter. INTRODUCTION During the honey flow bees provide themselves with food and accumulate winter food supplies. Rape honey is not suitable for bee wintering due to the high glucose concentration – fructose/glucose ratio from 0.86 to 1.0, which causes its crystallisation in combs (Ohe and Schonberger 2000). When melezitose content in honeydew honey is 8.0 – 12.0% or more, such honey crystallises in the combs. During winter bees are not able to consume such honey because they are short of water to dissolve the crystals and consequently, bees die of thirst (Gaіuszka et al 1996).

In the autumn, when honey is removed from hives, food reserves in the bee colonies are replenished with sugar syrup. When transferring sugar syrup to combs bees break down saccharose present in the syrup into glucose and fructose, for this they use their biological resources and up to 23.0% of the sugar syrup fed. These processes exhaust bees and they start wintering in a weakened condition. In order to prevent bee exhaustion resulting from syrup processing, it is expedient before winter to supply bees with ready made food, i.e. with syrup in which sugar has already been inverted. In inverted sugar saccharose is broken down into glucose and fructose, therefore the use of such food for bee feeding before winter exhausts bees less (Zaboenko 2000). Jachimowicz (1976) is of different opinion. According to this author, the bees must use up their hypopharyngeal glands secretion transferring the inverted syrup to the combs exactly the same as transferring the syrup made of refined sugar (saccharose). Sugar syrups produced from refined beet sugar and cane sugar are suitable for bee feeding. Impurities present in non-refined sugar are noxious to bees (Bailey 1966). It is suggested that refined sugar syrups are more suitable for bee feeding before winter compared with honey. The German factory Sudzucker produces high quality inverted sugar syrup, which contains 72.7% of sugar and 27.3% of water. The sugar content is composed of 30.0% sucrose, 31.0% glucose, 39.0% fructose, (Kammerer 1989). It is convenient for beekeepers to use inverted sugar syrup since it involves lower labour input. Some authors report that inverted syrup is less attractive to foraging bees, therefore robbing is not a problem with inverted sugar (Barker and Lehner 1974a). Inverted syrup produced from wheat starch was detrimental to bees since it contained undigested polysaccharides, especially starch (Doull 1974). Sugar syrups low in saccharose, but containing galactose, arabinose, xylose, mannose, raffinose, and lactose were not suitable for bee feeding (Barker and Lehner 1974b). The highest quality syrup is achieved using the enzyme invertase for the breakdown of saccharose. This enzyme present in honey breaks down saccharose to glucose and fructose. Therefore, using natural honey it is possible to produce inverted syrup. The Russian Institute of Apiculture in Rybnoje uses such sugar inversion: 72.5 kg of sugar, 7.5 kg of honey, 20 litres of water and 24 g of concentrated acetic acid (adjusted to 100%). The inversion of saccharose lasts for 5 – 6 days at 34 – 36°C (Strojkov 1990). In different honey types invertase activity is diverse and lower compared with that of commercially produced invertase, therefore production of inverted sugar with honey addition is time consuming. When pure invertase enzyme isolated from yeast is used for saccharose breakdown, microbiologically clean inverted sugar free of bee disease causal agents (pathogenic microorganisms) as well as noxious substances, is obtained (Strojkov 1990). Enzymatic yeast agent PCHELIT is currently being recommended for the production of inverted sugar syrup in Russia. This agent has been tested at the Institute of Apiculture in Rybnoje. According to producer’s description PCHELIT enriches inverted syrup with amino acids, lipids, B-group vitamins, and microelements. Wintering bees fed on sugar syrup inverted by PCHELIT, consume less pollen (by 40%) and sugar (by 20-30%) compared with the bees fed on sugar syrup (Bilash 2005). Sugar syrup should be acidified with organic acids (citric, oxalic, acetic, lactic). The best wintering results were obtained when 0.3 g acetic acid was added per kilogram of sugar to the sugar syrup, prepeared for feeding of wintering bees. The fecula mass in spring bees was lower when they were fed on sugar syrup, acidified with acetic acid, compared to those, fed on non acidified sugar syrup (Taranov 1986). Old honey (Jachimowicz and El Sherbiny 1975) or poorly inverted syrup high in HMF is not suitable for autumn feeding of bees, since this substance is toxic to bees. Jachimowicz and El Sherbiny 1975 found, that HMF is the factor that causes bee mortality. They report that the HMF content of 15 mg/100 g in commercially acid hydrolyzed invert sugar syrup significantly increased mortality of bees. After feeding sugar syrup with a HMF content of 15 mg/100 g, in average 58% of bees died within 20 days from the start of feeding. HMF concentrations 3 mg/100 g and 6 mg/100 g were harmless to the bees. As a result, many specialists recommend the proper concentration of this compound in inverted syrups not to exceed 2 mg/100 g as it is in most honeys (Kammerer 1989). The inverted sugar syrup should be used for bees only after checking HMF content in it (Jachimowicz 1976). When saccharose is inverted with organic acids, HMF formation is lower compared to inversion with mineral acids. It was found that 1% of acid used for saccharose inversion produces the following contents of HMF (mg/100 g sugar): lactic acid 61.4, citric acid 24.4, tartaric acid 56.8 and mostly phosphorus acid 112.1 (Strojkov 1990). The content of indigestible substances in the food intended for bee wintering should not exceed 0.1% to prevent overburdening of bee intestine during the winter period. High contents of HMF and mineral matters present in the food, as well as the presence of polysaccharids in it can cause diarrhoea in bees in the winter time (Ohe and Schonberger 2000; Jachimowicz and El Sherbiny 1975). Experimental objectives: - to assess the quality of differently prepared food for bee wintering;

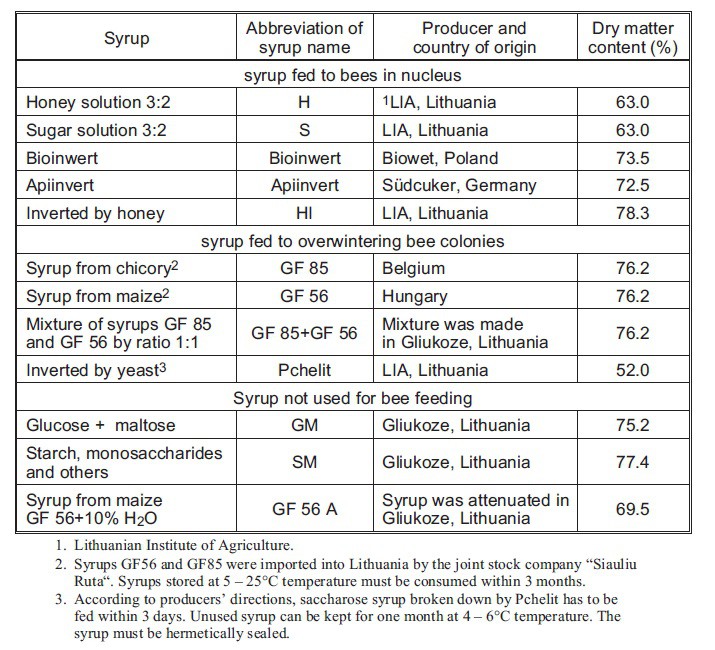

- to estimate the quality of syrups before feeding the bees and those stored in combs (after transferring them by the bees to the combs) - to compare the effects of various foods on wintering of honey bee colonies. MATERIAL AND METHODS Laboratory and outdoor experiments on bee winter feeding were performed at the Lithuania Institute of Agriculture, Department of Apiculture during the period 2000 – 2004. The details on the characteristics of sugar syrups, used for feeding bees in nucleus and for bees wintering are shown in Table1. Table 1. Investigation of the quality and suitability of syrups for winter feeding of bees.

PRODUCTION OF INVERTED SUGAR SYRUP WITH HONEY (HI) Three kilograms of sugar were added into 2 l of boiling water and the solution was stirred until sugar dissolved. When the syrup’s temperature had dropped to 35°C, 0.38 kg of honey was added and the syrup was well mixed. The syrup was kept for five days at 38 – 40°C and mixed twice a day. Five days later 1.2 g of cytric acid was added. The syrup was kept for another five days at 38 – 40°C and mixed twice a day. PRODUCTION OF INVERTED SUGAR SYRUP WITH YEAST (PCHELIT) Inverted sugar syrup was produced having dissolved 15 kg of sugar in 15 l of water and having added 6g of Pchelit yeast. The solution was mixed and stored at 25-30°C temperature for 48 hours and then within one week it was fed to bee colonies. NUCLEUS EXPERIMENT The syrups Bioinwert, Apiinvert and the ones produced at the Lithuanian Institute of Agriculture (Table 1) were used in the laboratory tests to study their quality and suitability for bee feeding in nucleus. As we found a high content of HMF in the syrup Bioinwert produced in 1999, we decided to perform tests in nucleuses in which bees were fed on inverted syrup in the nucleus placed under isolators outdoors. In summer 2000 – 2001 we watched the condition of bees fed on those syrups and tested the quality of stores from nucleus combs.

In order to identify the effect of inverted syrup on brood development the nucleus combs with a fertile Carniolan queen were transferred into the isolator frame of the bee colony for five days so that the queen could lay eggs. Afterwards the combs with eggs were transferred into nucleuses with 200 g young bees with infertile queens. After bees had sealed brood cells, the brood was transferred to the thermostat in which a set temperature of 35±0.5°C was maintained. HIVE EXPERIMENT Bee colonies wintered in the forest in the Dadant type of hives. Six bee colonies per treatment were used. The experiment was done in five apiaries in Kedainiai district. The experiments on bee feeding for overwintering were conducted during the period 2000 – 2003. The Carniolan bee colonies of the same strength with bee queensisters of the same age were used. The number of frames of wintering bees per bee hive was 7 – 8. Bees were fed on syrups GF 56, GF 85 and syrup GF 85 + GF 56 as well as sugar syrup Pchelit three times, from 9 to16 of September with a two-three day interval. In autumn honey present in combs was weighed prior to bee feeding for wintering. For wintering bees part of food is honey left in the combs and the other part of food was supplemented with inverted sugar syrup estimating 2.7 kg for one frame of bee colony. Colony strenght was estimated by the number of seams with bees and number of brood per hundred cells. In spring when the ambient temperature had risen to 15°C each colony’s strength was estimated again. The number of seams with alive bees and number of brood by hundred cells was measured. The remaining bee food in the beehive was weighed. Food consumption for winter was re-calculated by deducting remaining food in spring from the food stores left for winter. The amount of food consumed was re-calculated per comb. Frames with food were weighed with a KERN electronic pocket balance. The food stores from beehive frames after feeding bees were not assayed. Bee colonies were fed on the following sugar syrups:

- S; - GF 56; - GF 85; - GF 56+GF 85; - PCHELIT. LABORATORY EXPERIMENT Methods for assessing the quality of the sugar syrups and stored food from nucleus:

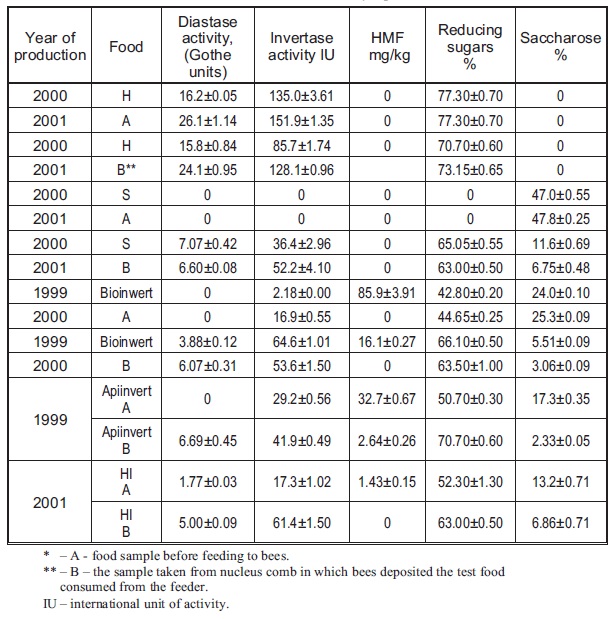

- content of reducing sugars and sucrose - after Lane-Eynon (CODEX STAN 12 – 1981) - content of HMF – after Winkler - content of mineral matter – by weighed ashed honey residues - content of moisture – after Wedmore - activity of diastase – after Schade - pH of the test sample was measured with a pH meter - activity of invertase – p-Nitro-α-D--glucopiranoside (pNPG) was used as a substrate for the determination of the invertase activity (Siegenthaler 1977) - electrical conductivity – after Vorwohl 1964 - sugar composition – by HPLC (Bogdanov and Baumann 1988) Laboratory analyses were replicated five times, sugar composition one time. Analysis of variance (ANOVA) was used for stastistical data processing. RESULTS AND DISCUSSION RESULTS OF SUGAR SYRUP QUALITY IN NUCLEUS EXPERIMENT The experiment showed that a bee organism performs a function of biological filter. The content of HMF which was present in the food declined in the syrup deposited by bees in the comb (Table 2).

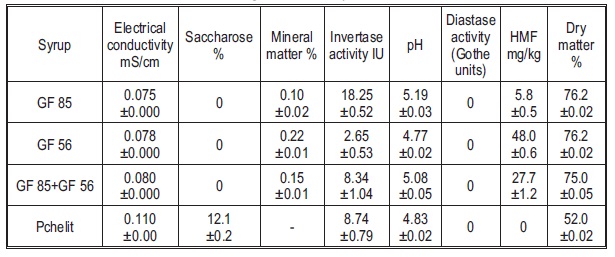

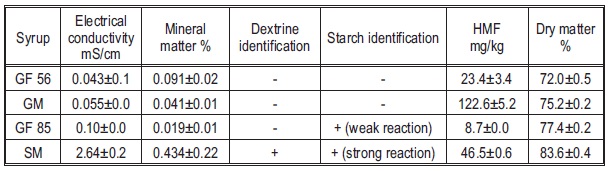

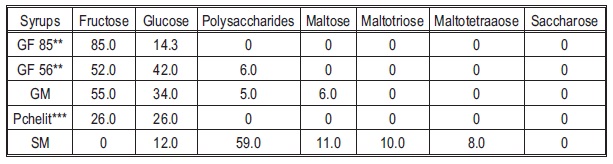

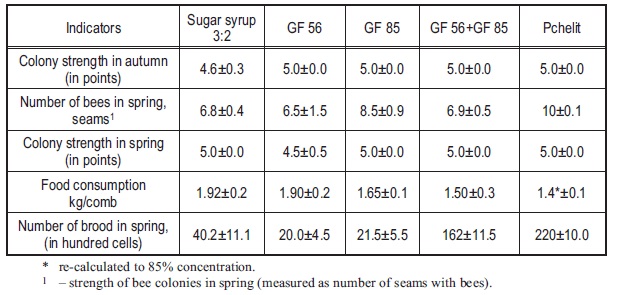

Table 2. Quality indicators of the syrups used in the laboratory tests and the food produced in nucleus from these syrups.  HMF content in the Bioinwert A and Apiinvert A from 1999 was 85.9 mg/kg. and 32.7 mg/kg, respectively. Its content in syrup Bioinwert B reached 16.1 mg/kg and in Apiinwert B 2.64 mg/kg. Bioinwert A from 2000 was better quality – HMF was not found in this syrup. In the syrup HI the HMF built up in a small amount – 1.43 mg/kg. Comparison of the composition of food fed to bees with that of the food deposited in combs showed that in many cases the food deposited in combs had higher contents of bioactive compounds – diastase and invertase enzymes. Diastase activity does not exist in Bioinwert A from 1999 and 2000 also in Apiinvert A from 1999. This component appears in Bioinwert B – 3.88 and 6.07 Gothe units and in Apiinvert B – 6.69. The low invertase activity was identified in Bioinwert A from 1999 and 2000 – 2.18 and 16.9 IU and Apiinvert A from 1999 – 29.2 IU. The activity of this enzyme increased in the Bioinwert B from 1999 – 64.6 and 53.6 IU and Apiinvert B – 41.9 UI. This experiment showed that new components pass from bee salivary gland secretion. Enzymes diastase and invertase are not present in syrups S (A). Those components were found in S (B). Diastase activity in syrup S (B) from 1999 and 2001 reached 7.07 and 6.60 Gothe units. The activity of invertase in S (B) from 2001 was practically identical with that of the syrup Bioinwert B from 2000, reaching 52.2 and 53.6 IU, respectively. Saccharose present in the syrups S (A) from 2000 and 2001 was 47.0% and 47.8% and due to increased invertase activity it declined in S (B) to 11.6 and 6.75%. The highest activity of enzymes diastase 15.8 and 24.1 Gothe unit and invertase 85.7 and 128.1 IU was in syrup H (B) from 2000 and 2001. Having analysed syrups GF 85, GF 56, and GF 85+GF 56 we identified the activity of invertase enzyme, which suggests that these syrups were produced by enzymatic method i. e. by breaking down sugar by invertase enzyme (Table 3). The pH of assayed syrups GF 56, Pchelit and GF 85+GF 56 was higher and close to that of honey compared to the syrup GF 85, which had lower pH 5.19. Investigation of Taranov 1986 cofirmed positive effect of sugar syrup acidified with organic acid for wintering bees. Table 3. The quality of the syrups imported by the Siauliai confectionery factory ‘Naujoji Ruta’ and sugar inverted by Pchelit.  Increased HMF content in syrups GF 85, GF 56 and GF 85+GF 56 suggests that these syrups were kept at a higher temperature or for a longer period than the product’s specifications allow. A high HMF content 48.0 mg/kg was identified for the syrup GF 56. Nevertheless, the highest content of HMF 48.0 mg/kg (4.8 mg/100g) in the sugar syrups imported by the Siauliai confectionery factory “Naujoji Ruta” seems to be safe to the bees, since Jachimowicz and El Sherbiny (1975) found its concentration up to 6 mg/100g of food harmless. Higher HMF content was identified the following year in the confectionery syrup furnished for the tests from the enterprise “GLIUKOZE” (Table 4). HMF in GM syrup was 122.6 mg/kg, and in SM amounted to 46.5 mg/kg. Table 4. Quality of syrup produced by the joint stock company “GLIUKOZE”.  High electrical conductivity of SM syrup 2.64 mS/cm and markedly higher mineral matter content 0.434%, compared with the syrups GF 56 and GF 85, suggest the presence of substances other than conventional sugars: glucose, fructose, and saccharose in these syrups. None of the syrups delivered for quality testing in 2003 were used for bee feeding. Two of them, however, according to their composition could be suitable as winter food for bees GF 85 and GF 56. The quality of syrup GF 85 tested in 2003 was lower compared with that in 2002. The composition of this syrup was slightly different in 2003: it had higher electrical conductivity, HMF and starch content (Table 3, 4). The composition of different sugars in the sugar syrup SM showed, that this syrup was particularly unsuitable for feeding of wintering bees because of the high content of polysaccharides present: 59.0%, maltose 11.0% and maltotriose (Table 5). The sugar syrup GF 85 contains 85.0% of fructose. When fructose content dominates over glucose content, sugar syrup does not crystallize in combs during the winter period (Ohe and Schonberger 2000). Table 5. The content of different sugars (%) in the syrups (in dry matter).  Table 6. Results of overwintering bee colonies fed on various syrups before winter (number of hives 6).  Results suggest that the confectionery syrups GF 56, GF 85 and GF 56+GF 85 used for bee feeding in 2000 – 2003 were suitable for bee wintering (Table 6). Our findings also indicate that when bees had been fed on the syrup GF 56 the strength of the bee colonies after wintering slightly declined from 5 points estimated in the autumn to 4.5 estimated in the spring perhaps because of the crystallization of the stores and the present of polysaccharides 6.0%. The highest food consumption per comb was identified for bees fed on GF 56, however those colonies reared fewer brood. In spring crystallisation of GF 56 syrup was observed in few cells of the comb. Having used sugar syrup GF 56+GF 85 the crystallization was not observed in spring. This sugar syrup was more efficient for bee wintering than GF 56 and GF 85 according to the number of bees in seams in spring, and brood number in hundred cells. The colonies fed on syrup PCHELIT were found to perform best in terms of brood rearing, since they consumed less food for brood rearing. All bee colonies survived through winter. CONCLUSION 1. The HMF content 85.9 mg/kg present in sugar syrup Bioinwert A from 1999 and 32.7 mg/kg in Apiinvert A, declined after feeding to bees by 5.3 and 12.4 times. HMF content of 48.0 mg/kg in sugar syrup GF 56 was harmless for wintering bees.

2. The electrical conductivity of sugar syrup is a valuable indicator showing the presence of mineral matter content in sugar syrup. 3. Syrup PCHELIT is effective for wintering bees due to lower sugar syrup consumption during wintering – 1.4 kg/per comb compared to the consumption of sugar syrup 1.92 kg/per comb. 4. The highest number of brood 220 was found in the bee colonies fed for wintering on sugar syrup PCHELIT, compared with the colonies fed on sugar syrups S, GF 56, GF 85 and GF 56 + GF 85 were number of brood was 40.2, 20.0, 21.5 and 162 in hundred cells, respectively. 5. Having used sugar syrup GF 56 + GF 85, no crystallization was observed in spring. The inappreciable crystallization of sugar syrup GF 56 in spring did not have any negative effect on bees. REFERENCES Bailey R. J. (1966) – The effect of acid-hydrolyzed sucrose on honeybees. J. Apic. Res. , 5: 127 – 136. Barker R. J., Lehner T. (1974a) – Influence of diet on sugars found by thin-layer chromatography in thoraces of honey bees, Apis mellifera. L. J. Exp. Zool., 188:157 – 164. Barker R., J., Lehner Y. (1974b) – Food choice changes in aging honey bees. Ann. Entomolog. Soc. Am., (67): 717 – 718. Bilash N. G. (2005) – Iskusstvennye korma. Pchelovodstvo, 8: 12 – 14. Bogdanov S., Baumann E. (1988) – Bestimmung von Honigzucker mit HPLC. Mitt. Gebiete Lebensm. Hyg., (79): 198–206. Doull K., M. (1974) – Trials with commercial sugar syrups as supplementary or maintenance food for honeybees. Aust. Bee J., 55 (2), 17-19. CODEX STAN 12 (1981) – Codex Alimentarius Commission. Codex alimentarius. Codex standards for sugars (including honey), Rome 3:1-53. Gaіuszka H., Koteja J., Tworek K. (1996) – Pszczoіy na spadzi. Wyd. Sadecki Bartnik. Nowy Sacz: 69 – 73. Jachimowicz Th. (1976) – Wozu brauchen wir Invertzucker bei der Biennenfutterung. Bienenvater, 5:131-133. Jachimowicz T. and El Sherbiny G. (1975) – Zur Problematik der Verwendung von Invertzucker fur die Bienenfutterung. Apidologie, 6: 121–143. Kammerer F. X. (1989)– Aktueller Stand der Erkenntnisse uber die Futterung von Bienen mit Zucker. Imkerfreund, 1: 12-14. Ohe W., Schonberger H. (2000) – Futtersirup im Vergleich. Deutsches Bienen Journal, 8: 312-314. Strojkov S. A. (1990) – Invertirovannyj sirop. Pchelovodstvo, 7: 27–28. Siegenthaler U. (1977) – Eine einfache und rasche Methode zur Bestimung der alpha-Glucosidase (Saccharase) im Honig. Mitt. Geb. Lebensmittelunters. Hyg., 68, 251–258. |